Metallic Fuel Testing Program

The Integral Fast Reactor (IFR) program, active from 1984 to 1994, produced a large collection of data relating to the performance of metallic fuels in sodium-cooled fast reactors (SFRs). To evaluate fuel/cladding compatibility, tests were conducted under both steady-state and transient conditions. Steady-state tests were first conducted within test reactors to evaluate fuel performance during normal reactor operating conditions. During steady-state reactor operation, solid state interdiffusion at the fuel-cladding interface within a fuel pin causes slight cladding wastage, which is highly dependent on the local power, temperature, and burnup of the fuel. While this wastage is not a concern under normal operating conditions, the metallic fuel pin may be more vulnerable to off-normal events (e.g., loss of coolant flow, loss of a heat sink, or transient overpower events). Transient tests are used to evaluate fuel performance during these off-normal events. During these transient scenarios, the fuel pin will experience elevated temperatures, at which uranium and plutonium from the fuel can react with iron and other components in the cladding, forming liquid phases (eutectic formation). Eutectic formation at the fuel-clad interface reduces the cladding thickness and may compromise its integrity. While these off-normal events can be simulated in-pile (e.g., in the TREAT reactor), they can also be simulated out-of-pile by raising fuel samples rapidly to high temperatures representative of these accident scenarios. The furnace transient testing program conducted in the Alpha-Gamma Hot Cell Facility (AGHCF) used irradiated fuel samples, primarily from EBR-II, with fuel-clad interfaces prototypic of those found in an operating reactor. Records from the transient tests conducted out-of-pile in the AGHCF are archived in the Out-of-Pile Transient Database (OPTD).

IFR Fuel Compatibility Testing

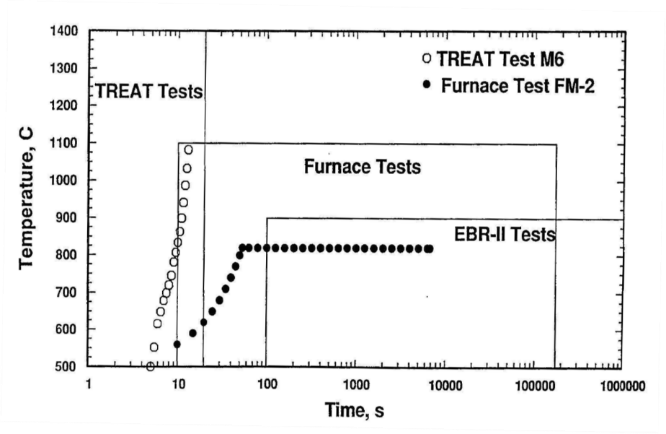

For a clearer picture of where the AGHCF furnace transient tests fit in the larger landscape of IFR fuel compatibility testing, they can be compared to both the transient testing conducted in TREAT and the steady-state testing conducted in EBR-II. The tests of metallic fuels conducted in EBR-II were lower temperature, steady-state tests to demonstrate the performance of the fuel under normal operating conditions. Records of these EBR-II tests can be found in FIPD [1] and PADB [2]. An extensive long-duration transient testing program was also conducted at EBR-II as documented in the EBR-II Transient Test Database (ETTD) [3]. The transient tests conducted on metallic fuels in the TREAT reactor were high temperature, short duration transient tests to demonstrate the fuel behavior under rapid transient conditions, and their records are found in the TREXR database [4]. The AGHCF furnace tests included in OPTD bridge the gap between the EBR-II and TREAT testing conditions; they exposed irradiated fuel samples to elevated, accident-scenario temperatures for times in the range of minutes to hours, as shown in Figure 1.

Furnace Transient Tests and Results

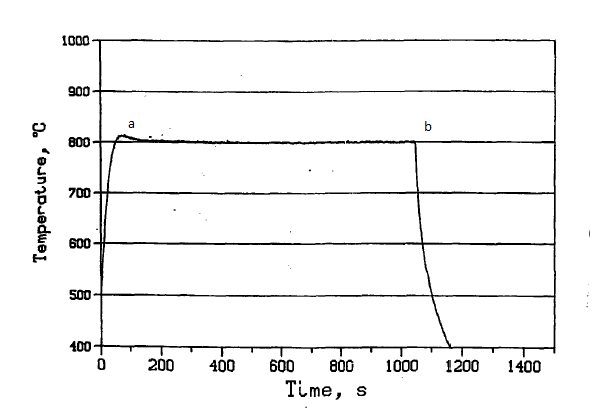

The out-of-pile furnace transient tests included in OPTD were conducted in two different furnace apparatuses at the Alpha-Gamma Hot Cell Facility at Argonne National Laboratory: The Whole Pin Furnace (WPF) and the Fuel Behavior Test Apparatus (FBTA). These furnace apparatuses heat-tested fuel pins or pin segments taken from EBR-II subassemblies. Prior to furnace testing the samples, pre-test examinations of the fuel and cladding were made to characterize the as-irradiated structure. To begin the temperature transient test, the sample was installed in the furnace and slowly ramped to a pre-test, priming temperature. The prescribed furnace transient routine then began by increasing the temperature at a predetermined rate (ramp rate) to a peak target temperature. A representative furnace testing routine is shown in Figure 2. The sample was held at the target temperature for a designated period of time or until pin failure. The furnace was scrammed when the test end condition was met (either at the end of the test time, or when pin failure was detected by a pressure spike), and the pin was then allowed to cool by convective heat loss. Following each test, data was collected and post-test examinations were made of the sample.

The FBTA tests were conducted on more than 140 fuel pin segments extracted from EBR-II fuel pins (and a few from FFTF) at constant temperatures from 625 to 850°C for durations from a few minutes up to 36 hours (most had a 1 hr duration). Fuels tested were U-10Zr and ternary fuels (up to U-26Pu-10Zr), with claddings composed of HT9, D9, or 316 stainless steel and peak burnups from 2.3 to 17%. A few tests were also conducted on ternary fuels with varying Zr content. The results of the FBTA tests established the time- and temperature-dependence of eutectic cladding penetration in the metallic fuel samples as well as rough threshold temperatures for liquefaction. The Whole Pin Furnace (WPF) tests were conducted on intact fuel pins from EBR-II, rather than segments, to study synergistic effects of fission gas pressure loading and fuel-cladding interaction. Seven WPF tests determined modes of pin failure, established safety margins and fuel failure thresholds, and examined fuel motion within the pin. More detailed descriptions of the furnace apparatuses, tests conducted, and key results can be found in ANL-ART-149, OPTD: Out-of-Pile Transient Database.

Motivation for a Database

Documentation of the furnace tests was scattered, found in a variety of locations ranging from private offices to file cabinets in storage areas. Much of the recorded information about the tests, particularly lessons learned and comments relating to design of the tests, does not exist in the formal reports, but rather in informal, internal memos and notes. Without an effort to digitally archive these documents, they may have been lost to time. Including these records in a linked digital archive allows a user to see all of the relevant documents for a particular test collected together, giving the most complete context for understanding the test and results. OPTD provides a means for an interested person to go about locating and accessing the records they need from the collection.